- Home

- References

References

In 2017 A TEC has engineered an alternative fuel system for kiln riser duct firing in Slovakia. The Turna cement plant has already operated a SAF system for the main burner which consists mainly of a double truck docking station and a dosing system.

A TEC has installed an XMercury plant in Allmendingen together with Scheuch GmbH. The plant components have been integrated in the preheater tower.

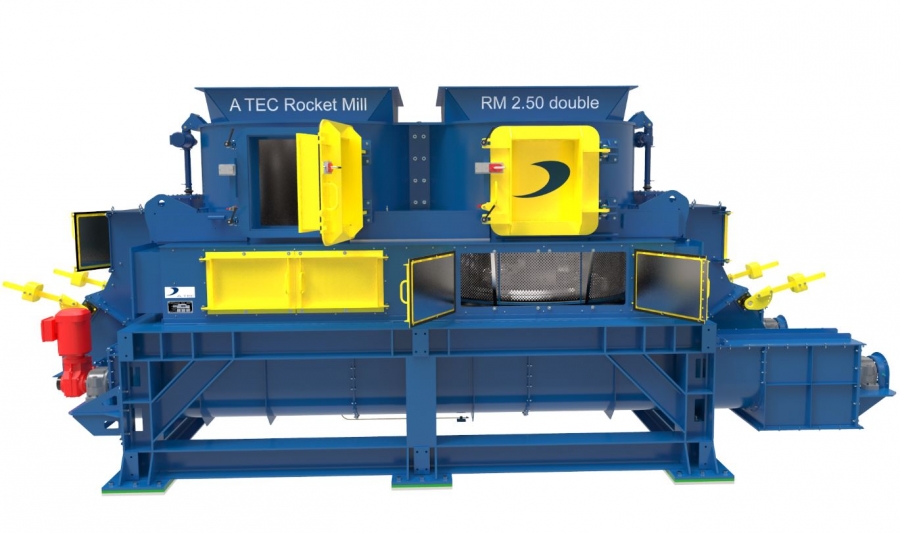

A TEC Plant Construction in Eberstein is manufaturing two Rocket Mill's at the moment. They will be installed at Repower South, an advanced recycling, recovery and renewable energy company in the USA.

A TEC installed a new separate-line calciner in Denmark in 2017. The aim of the project is to adapt the flow characteristics of the calciner system to improve the operation behaviour of the system signifcantly.

Read more ...A TEC has built a new calciner for Lafarge Holcim‘s plant in Mannersdorf, Austria.The new calciner is erected in an 80m high tower next to the already existing heat exchanger tower.

Read more ...Omya Calcita s.r.l. placed the order of one HURRICLON for their plant in Bucarest, Romania. A TEC will provide the design and supply of one cyclone type Hurriclon 1600 CT 750 which will be used as a de- dusting unit for calcium carbonate of ground marble.

The existing preheater tower at BATIÇIM‘s plant in Izmir will be upgraded and A TEC takes care of engineering, supply of key equipment and commissioning in this regard.

To optimize the production of highly caloric residue-derived fuels for the cement industry the Austrian company .A.S.A. installed A TEC’s Rocket Mill® RM 2.50 double in their treatment plant in Wiener Neustadt.

Read more ...A TEC provided LafargeHolcim’s plant with an alternative fuel chlorine by-pass increased system for the clinker line in 2016. The existing bypass system (designed by A TEC) has a design bypass rate of 5 % (5.000 Nm³/h kiln gas removed) using a two stage air queching step. After realising the project the bypass rate will be increased up to 10 %.