- Home

- Products & Processes

- Products

- Rocket Mill

Rocket Mill

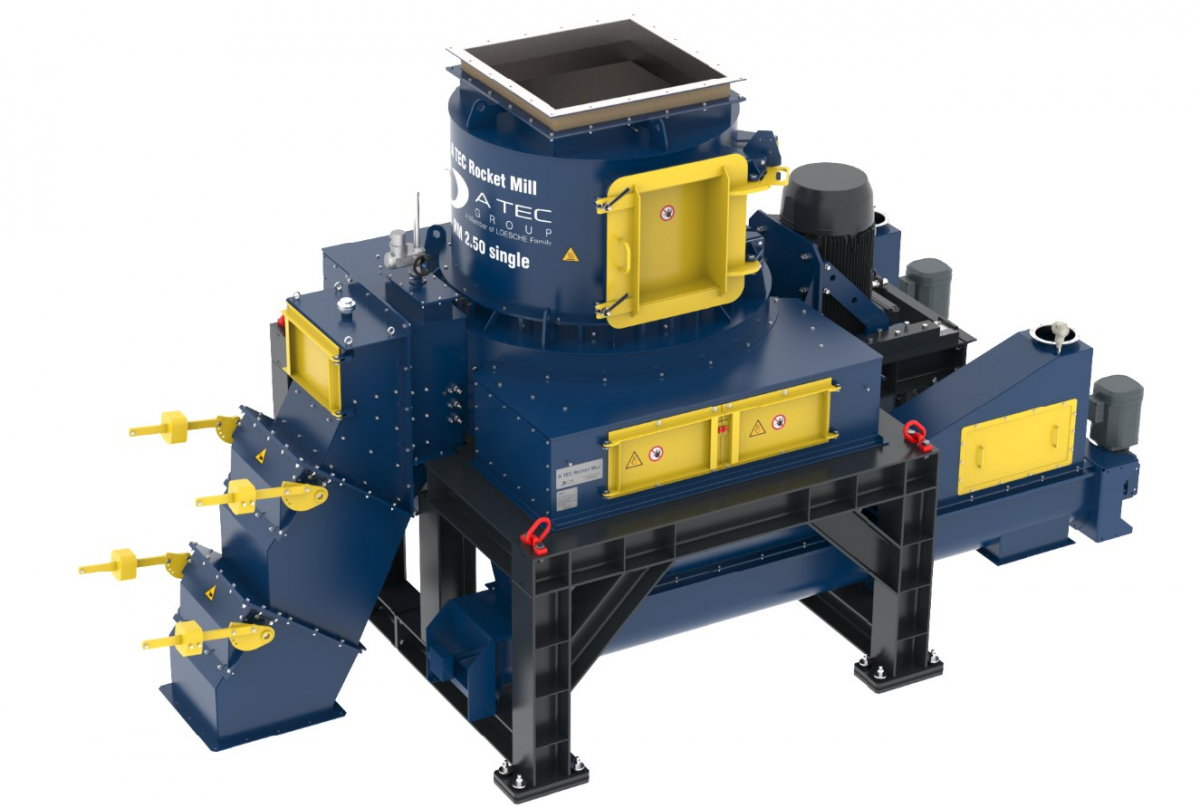

A TEC Rocket Mill 2.50 Single

A TEC Rocket Mill 2.50 Single

The Rocket Mill is A TEC’s innovation for alternative fuel preparation which combines drying, grinding and homogenizing in one step. Even compound materials such as wind rotor blades made of GRP or CFRP can be processed. The above-mentioned properties are also an essential and important parameter for further process steps when processing biomass.

A significant advantage of the A TEC Rocket Mill is that the raw needs to be pre-shredded only, and heavy impurities such as metals shall be removed. During the shredding process in the A TEC Rocket Mill, residual heavy materials are further separated from the finished product, such as metals, stones and other impurities. This offers the advantage to increase the fuel quality by an increase of the calorific value of the materials shredded for fuel production. If used for recycling applications, the separation of different materials allows a better downstream separation of materials.

Especially in the production of alternative fuels, the end product of this shredding process is a high-quality alternative fuel with which significantly higher substitution rates can be achieved.

Summary:

Advantages:

Advantages for the downstream process:

Types of products:

Test plane A TEC Rocket Mill 2.00 Single

The A TEC Rocket Mill 2.00 Single is in operation as a test plant with a drive power of 315 KW. The system is equipped with a feeder adapted to the mill for the raw and feed material, as well as a separate dedusting system. The test plant is characterised by the fact that larger quantities of input material can be fed directly from a truck moving floor trailer to the mill and the finished material can then be fed back into a truck moving floor trailer. The customer has the option of feeding his own material to the test plant and transporting the finished product back to his lorry.

-

Ansprechpartner

-

Ansprechpartner