- Home

- Products & Processes

- Products

- Pendulum Flap

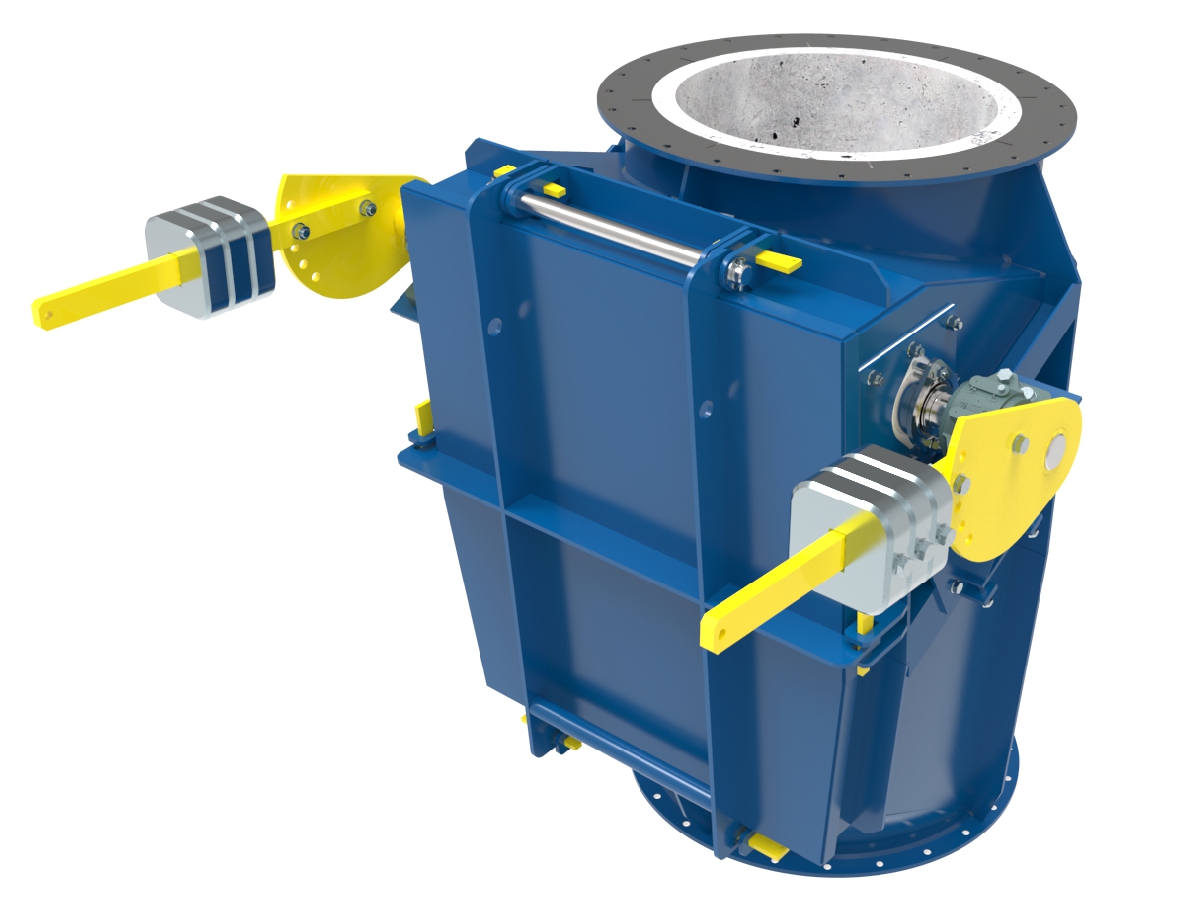

Pendulum Flap

Pendulum Flap

Pendulum Flap

For best tightness and more efficiency:

- Easily adjustable

- Maintainable in position

- Operational reliability

Pendulum Flaps in cement preheaters have the function to avoid counter gas flow through material pipes between two stages of the preheater. Such counter gas flow leads to unwanted heat loss and build-up formation in meal ducts and results in drastic reduction of the separation efficiency of the cyclone above.

The importance of well functioning pendulum flaps is often neglected by operators. High specific energy consumption (kcal/kg clinker) and poor separation efficiency of the cyclone causing large quantities of re-circulating dust in the system as well as high quantities of dust loss into the kiln filter are the costly consequence.

Based on many years of experience gained in cement plants around the world, A TEC has designed a unique type of PENDULUM FLAP which overcomes the problems usually faced with conventional pendulum flaps.

It’s main features are:

- Easy installation, even in existing meal pipes

- nearly 100% airtight sealing

- Easy maintenance (cleaning) due to special bearing of the flap shaft allowing movement of the flap in three axis directions. The flap can be easily swiveled out of the casing through the special maintenance opening, which is a unique feature of A TEC’s pendulum flaps

- Long durability due to application-specifically selected materials and easy maintenance

- Installation with or without refractories possible

-

Ansprechpartner

-

Ansprechpartner