A TEC - innovative technologies for tailor-made solutions

When it comes to outstanding technological performance, you need experts who think ahead.

Innovators who always go a step further. Significant efficiency improvements, sustainable cuts in energy consumption, compliance with or even overachievement of environmental limits - our solutions give a competitive edge to our customers.

A TEC - News

NCB Conference in Delhi - November 2024

21.01.2025 | Award Winning Presentation

A TEC had the privilege of presenting at the National Conference & Exhibition on Cement, Concrete, and Building Materials in Delhi, held from November 27 to 29, 2024.

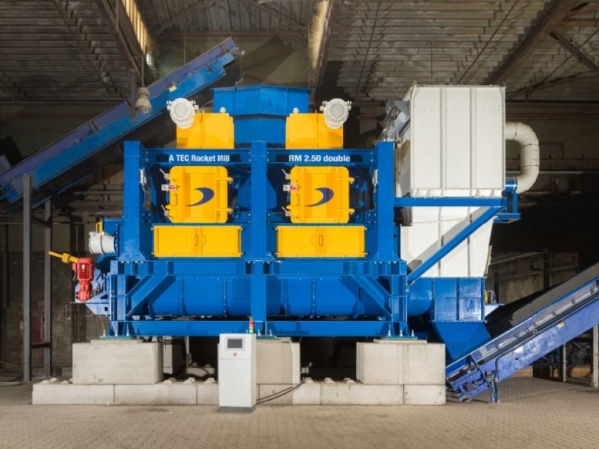

Our paper, titled “Maximizing Solid Alternative Fuel Quality with the A TEC Rocket Mill and A TEC Flash Dryer,” was well-received and even earned an award.

The conference featured approximately 141 technical presentations, 15 or more keynote speeches, and 133 exhibitors, including many major OEMs from the cement industry. We were proud to contribute and be part of such a prestigious event.

Installation of A TEC's High Efficiency Cyclones (HEC)

21.01.2025 | From order to commissioning in only 4 months

To improve and refurbish the existing dust settling chambers at the clinker cooler of the kiln line for a cement plant in France, A TEC Production & Services GmbH was awarded a contract to replace the existing system with A TEC’s high efficiency cyclones (HEC) by end of 2023. A TEC also took responsibility for the clinker dust handling and the design of the gas routing.

The scope of supply for this order included complete engineering, supply and mechanical erection works incl. the required dismantling of the existing dust settling chamber which is worn out. Therefore, A TEC will executed this project on an EPC basis for the plant.

With the new A TEC HEC Cyclones, the plant will benefit from high separation efficiency and low maintenance by using suitable wear resistant materials.

The installation was completed in record time: From order to commissioning only 4 months were available where 3D scan, process design, engineering for manufacturing, manufacturing and supply as well as dismantling and mechanical erection was done. The project was finished in Q1/2024 on time.

Copyright © 2017 - A TEC Production & Services GmbH