- Home

- News

News

21.01.2025 | Award Winning Presentation

A TEC had the privilege of presenting at the National Conference & Exhibition on Cement, Concrete, and Building Materials in Delhi, held from November 27 to 29, 2024.

Our paper, titled “Maximizing Solid Alternative Fuel Quality with the A TEC Rocket Mill and A TEC Flash Dryer,” was well-received and even earned an award.

The conference featured approximately 141 technical presentations, 15 or more keynote speeches, and 133 exhibitors, including many major OEMs from the cement industry. We were proud to contribute and be part of such a prestigious event.

21.01.2025 | From order to commissioning in only 4 months

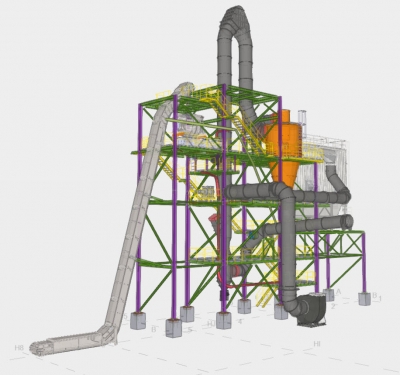

To improve and refurbish the existing dust settling chambers at the clinker cooler of the kiln line for a cement plant in France, A TEC Production & Services GmbH was awarded a contract to replace the existing system with A TEC’s high efficiency cyclones (HEC) by end of 2023. A TEC also took responsibility for the clinker dust handling and the design of the gas routing.

The scope of supply for this order included complete engineering, supply and mechanical erection works incl. the required dismantling of the existing dust settling chamber which is worn out. Therefore, A TEC will executed this project on an EPC basis for the plant.

With the new A TEC HEC Cyclones, the plant will benefit from high separation efficiency and low maintenance by using suitable wear resistant materials.

The installation was completed in record time: From order to commissioning only 4 months were available where 3D scan, process design, engineering for manufacturing, manufacturing and supply as well as dismantling and mechanical erection was done. The project was finished in Q1/2024 on time.

07.11.2024 | Every year it is a pleasure!

On November 7, 2024, we had the pleasure to participate once again in the career day at HTL 1 Lastenstraße in Klagenfurt.

For A TEC, it was a successful and rewarding opportunity to introduce our company to the pupils.

We were delighted by the high level of interest, which was evident through the many questions and engaging conversations.

A big thank you to HTL for the excellent organization.

We look forward to welcoming talented young professionals in our team.

15.01.2025 | Save the date, 06 March 2025, Montanuniversity Leoben.

Visit our booth at the upcoming career fair Teconomy Leoben and talk to us to learn more about our company.

We can't wait to connect with you, share insights, answer questions and explore potential opportunities together.

See you there! 🙂

07.11.2023 | Once again, we had the privilege of participating in the Career Day at HTL 1 Lastenstraße in Klagenfurt.

The event proved to be an incredibly successful and enlightening opportunity for A TEC to present our company to the students.

We were delighted with the students' keen interest in our industry's career potential, as evidenced by their numerous questions and engaging discussions.

Our sincere thanks go to HTL for their exceptional organization. We look forward to welcoming talented young professionals to our team!

- Most Innovative Technology Award for our A TEC Rocket Mill, as chosen through online voting on the Global CemFuels homepage. Despite fierce competition from established names in the cement industry, our technology shone as a beacon of innovation in alternative fuels processing.

- Global CemFuels Personality of the Year Award bestowed upon our very own Michael Suppaner. This accolade reflects Michael's unwavering dedication and enthusiasm over the decades at A TEC P&S, relentlessly pushing for efficiency and environmental optimization across the global cement industry. His fervent advocacy for CO2 emissions reduction, aligning with A TEC Production and Services GmbH's primary objective, has been inspiring and motivating.

- Best Presentation of the Conference Award again went to Michael Suppaner for his engaging talk titled "The Optimised Fuel for Optimised Combustion." In his presentation, Michael passionately encouraged cement plant operators to boldly pursue higher thermal substitution rates with alternative fuels. Despite the initial costs and investments required for the necessary equipment, Michael proficiently illustrated through tangible data that the Return on Investment (RoI) is highly attainable with a short payback period.

18.10.2022 - In October we attended the HTL 1 Lastenstraße's Company Day 2022 in Klagenfurt, Austria.

HTL 1 Lastenstraße puts young talent and company representatives in close contact during its Company Day. This innovative event presents an outstanding occasion for companies to discover the future generation of professionals, learn about their career goals and aspirations as well as finding potential candidates who are knowledgeable, curious and willing to learn.

During the event, we had the opportunity to present to the students an outlook on the cement industry and our role in this market focused on optimization and efficiency improvement of cement plants, from optimal process, and mechanical design to fuel optimization, and alternative fuels implementation.

We are excited to welcome young future professionals into our team and we look forward to receiving your applications!

01.05.2021 - A TEC has been awarded with a mechanical turn key scope to install a Flash Dryer for alternative fuels and new Alternative fuel system for the kiln burner at Királyegyháza Cement Plant, near Pecs, in Hungary (LAFARGE Cement Hungary Ltd.).

07.04.2021 - A TEC has been awarded in cooperation with Aliacem s.r.o. for the project of new preheater cyclones including riser ducts for stage four of the double string preheater at Lafarge Mannersdorf (Austria). The new design by A TEC will reduce the pressure drop and increase preheater efficiency. The project will be realized in the upcoming winter maintenance stop 2022.

More Articles ...

- Two Rocket Mills for Ssang Yong Cement Co. (South Korea)

- New calciner line for LafargeHolcim's plant

- New Management for the A TEC Group

- 14th TCMB International Technical Seminar and Exhibition in Turkey

- Semi-mobile version of Rocket Mill® launched

- Loesche Plant Tour in Austria

- Alternative Fuel System has been installed at CRH

- Termokimik orders A TEC cyclones

- Two new A TEC calciners for Aalborg Portland Cement